- Services

Sheet Metal Fabrication Service

Custom sheet metal parts and assemblies in as fast as 1 day. Get an online quote today.

Jump to Section

Sheet metal is a versatile manufacturing process for a range of metal components. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Common sheet metal parts include:

- Electrical enclosure

- Parts for computer electronics

- Chassis

- Brackets

- Cabinets

- Mounts

AMPERE FUTURE Sheet Metal Fabrication Capabilities

Size: 47 in. x 119 in. OR 1,193.8mm x 3,022.6mm (max)

Bend length: 10 ft. OR 3.048m (max)

Flat part: 0.5 in. x 0.5 in. OR 12.7mm x 12.7mm(min)

Formed part: 1.5 in. x 1.5 in. OR 38.1mm x 38.1mm (min)

Bends: +/- 2 degree

Offsets: +/- 0.024 in. (+/- 0.608mm)

Hole Diameters: +/- 0.010 in. (+/- 0.254mm)

Edge to Edge/Hole; Hole to Hole: +/- 0.010 in. (+/- 0.254mm)

Hardware to Edge/Hole:+/- 0.020 in. (+/- 0.508mm)

Hardware to Hardware: +/- 0.030 in. (+/- 0.762mm)

Bend to Edge: +/- 0.020 in. (+/- 0.508mm)

Bend to Hole/Hardware/Bend: +/- 0.030 in. (+/- 0.762mm)

Features Separated By Two or More Bends: +/- 0.060 in. (+/- 1.524mm)

Our Sheet Metal Material Options

- Aluminum:Al 5052, 6061

- Brass:C260

- Copper:C101, C110

- Stainless Steel:SS 301, 304, 316/316L

- Steel Mild Low Carbon

Sheet Metal Finishing Options

Looking for more than a few basic sheet metal parts? We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof.

- Anodized

- Bending

- Forming

- Heat treated

- Laser welded

- Painted

- Plated

- Powder coated

- Riveted

- Screen printed

- Tapped

About Sheet Metal Fabrication

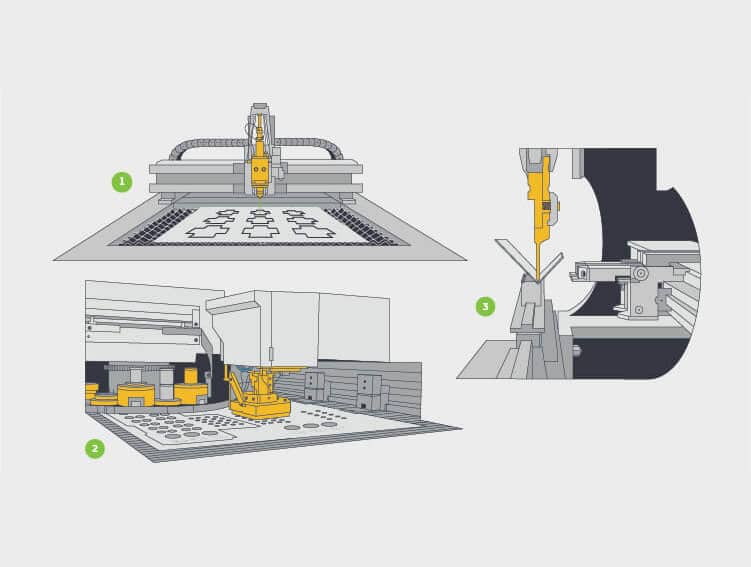

During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Depending on the part geometry, a sheet metal punch (2) can form additional features. Once the parts are deburred, they move to the press brake (3) where they are formed into the final geometries. Additional secondary operations are often used to finish the sheet metal parts.

Sheet Metal services come in a variety of capabilities such as bending, shearing, staking, and stamping. These parts are commonly used in drilling, tapping, counterboring, and countersinking operations. Sheet metal parts can fit many projects, from simple bent sheet metal prototypes to production runs of complex, multi-part assemblies.