- Services

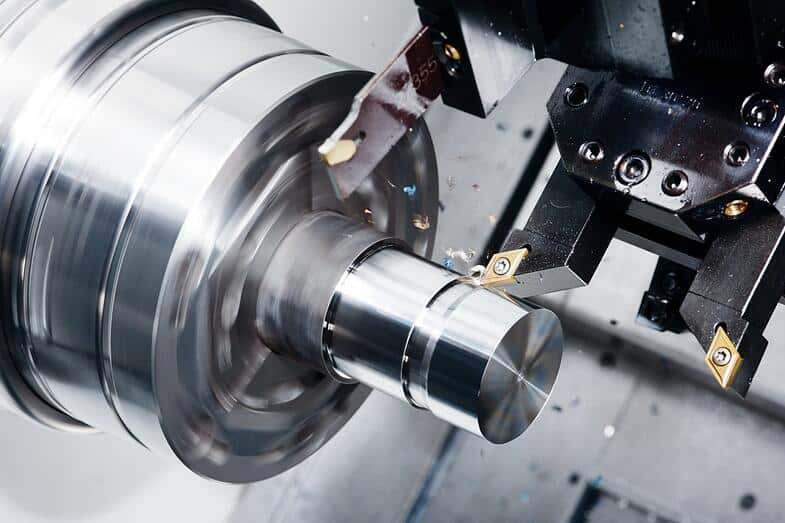

CNC Turning Service

Get quality custom turned parts for rapid prototyping and end-use production.

Jump to Section

CNC turning is often used for:

- functional prototypes and end-use parts

- parts with cylindrical features

- parts with axial and radial holes, flats, grooves, and slots

AMPERE FUTURE CNC Turning Capabilities

Our basic guidelines for CNC turning include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| US | Metric | ||

| Maximum Dimensions | Diameter | 3.95 in. | 100.33mm |

| Length | 9 in. | 228.6mm | |

| Minimum Dimensions | Diameter | 0.16 in. | 4.07mm |

| Length | 0.05 in. | 1.27mm | |

| Wall Thickness | 0.020 in. | 0.51mm | |

| Angle | 30° | 30° | |

| Tolerances | +/- 0.005 in. | +/- 0.13mm | |

Additional Notes on CNC Turning Guidelines

● Small features may be allowed, but the diameter in any region should not be less than 0.030 in. (0.76mm).

● Sharp conical points are allowed; angles should be greater than 30 degrees. Walls thinner than 0.020 in. (0.5mm) typically do not survive the machining process.

CNC Milling Materials

We stock a range of metal materials that are suitable for various part applications and industries. Choose from aluminum, brass, low carbon steel, stainless steel, steel alloy, and titanium for turned parts.

- Aluminum

- Brass

- Stainless Steel

- Steel Alloy

- Low Carbon Steel

- Titanium

CNC Milling Surface Finishes

Here is a wide selection of metal surface finishing services at your choice for the machined CNC Turning parts to improve the part appearance, surface smoothness, corrosion resistance, and other characteristics.

| As machined | Description |

|---|---|

| As machined | Standard finish with a surface roughness of 1.6 μm (126 μin). |

| Smoothing | The standard smoothing surface roughness (Ra) is 0.8 μm (63 μin). |

| Painting | Spraying paint, pigment, or color to a solid surface as a colored protective layer. |

| Passivation | Remove ferrous contaminants or use a light coat of protective material to create a shell. |

| Powder Coating | A functional and decorative finish that is applied as a free-flowing, dry powder. |

| Anodizing | Type II (anodizing color or clear) or Type III (anodizing hard coat) |

| Polishing | Produce a smooth and shiny surface. |

| Black Oxide | Forming a black conversion coating on metal parts. |

| Bead Blasting | Removing surface deposits by applying fine glass beads at a high pressure. |

| Abrasive Blasting/Sandblasting | Smoothing and cleaning a hard surface by forcing solid particles across that surface. |

| Electroplating/Plating | Form a thin coherent metal coating on an electrode. |

| Brushing | Polishing the metal with grit resulting in a unidirectional satin finish. |

| Chromate Conversion Coating | Increase the corrosion resistance while maintaining conductive properties. |

About CNC Turning

CNC turning is a subtractive manufacturing process that rotates a metal rod while a cutting tool is held against the stock to remove material and create final parts. Our CNC lathes are also equipped with live tooling that can machine flat features and holes into the workpiece. Outside diameter (OD) and inside diameter (ID) threading is also available.

There are many types of CNC turning operations for CNC lathe services can be performed on a live tooling lathe in CNC turning factory, including Hard turning, Parting, Facing, Boring, Reaming, Taper turning, Drilling, Knurling, Threading, Grooving, etc., comes in varying tools, cost and set-up time.